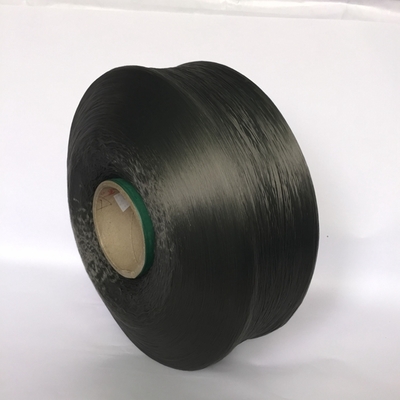

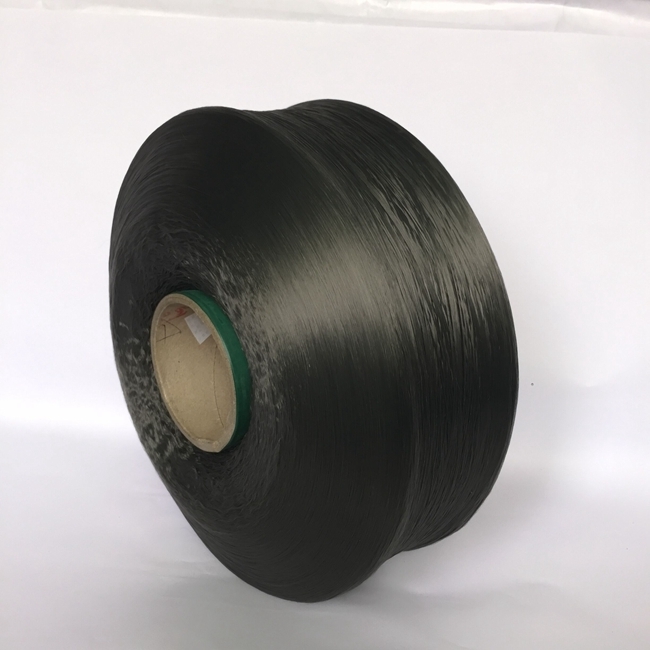

Factory Direct 900D–1100D Colored PP Yarn — High-Tenacity FDY Polypropylene Multifilament

Product Summary

Factory-made 100% polypropylene (FDY) multifilament tape yarn available in ~900D (also 300-1680D range), factory-dyed, medium-coarseness and engineered for webbing, braided rope and heavy-duty textile applications.

Product Parameters & Technical Specs

- Model: XCF900C12.

- Material: 100% polypropylene (PP).

- Process: FDY (Fully Drawn Yarn), multifilament tape yarn; combination of short fibers and continuous filament.

- Filament options: 36f / 55f / 60f.

- Nominal linear density: 900 ± 20 D (other Dtex options listed by supplier: 300D-1680D).

- Tenacity / Break strength: Tenacity ≥3.5 g/d, Break strength ≥35.3 (supplier test specs).

- Elongation at break: ~20.0% ± 2.0. CV tolerances: linear density ≤2.0, tenacity CV ≤6.5, elongation CV ≤4.0.

- Air-intermingled: ~20-25 pcs/m (available).

- Oil pickup: 1.0-1.2.

- Production capacity: ~2,500 tons per month.

Main Selling Points

- Consistent, industry-grade performance: Tight CV tolerances and factory testing deliver predictable strength and elongation for downstream weaving/braiding.

- Factory-dyed color options: Saves downstream dyeing steps; suitable for brand-matching (custom colors available subject to MOQ).

- Versatile denier range: While this listing highlights 900D, the supplier offers a broad range (300-1680D) for both light and heavy-duty needs.

- Competitive factory supply: Direct factory sales with in-stock capacity and bulk monthly output make it suitable for OEMs and distributors.

Typical Application Scenarios

- Woven and knitted webbing for luggage, straps and cargo belts.

- Braided or twisted rope -- luggage ropes, general-purpose braided lines and safety ropes.

- Industrial textiles such as geotextiles, anti-fall nets, filter cloth and wind canvases.

- Handles, cords and accessories where color and tenacity are both important.

Packaging, Shipping & Lead Time

- Packing: ~5-7 kg per bobbin; 4 bobbins per sack/box.

- Container load: ~10 tons/20'GP; ~23.5 tons/40'HQ.

- Typical delivery: 7-15 days after receipt of down payment or irrevocable L/C (supplier quotes fast turnaround and sample availability).

Quality Assurance & Supplier Snapshot

Manufacturer: Guangdong Xinchengfa Industrial Co., Ltd. -- established 2010, specializes in PP multifilament yarn and webbing, exports globally and claims SGS-level quality control and OEM/ODM service. Production claims include in-stock capacity and repeated buyer customers. (Verify certificates directly with supplier.)

Market Trends & Why This Yarn Will Stay Relevant

- Demand for ready-to-use colored yarns: Brands and manufacturers prefer pre-colored yarn to reduce water, energy and process steps.

- Growth of technical textiles: Increased use of PP yarn in geotextiles, safety nets and industrial strapping supports steady demand for mid-to-high deniers like 900D.

- Sustainability direction: Expect rising demand for recycled-PP and low-impact dyeing processes; future product lines may highlight recycled content and eco-certifications. (Request supplier documentation for any green claims.)

FAQ

Q: Can I get a sample?

A: Yes -- supplier offers free samples; customer usually covers express shipping.

Q: How long to receive samples?

A: Existing/in-stock items: within ~3 days.

Q: Are custom colors available?

A: Yes -- colors can be customized provided MOQ requirements are met.

Q: What testing/quality controls are used?

A: Supplier states strict in-process detection and sampling inspection before shipment. Ask for SGS or third-party test reports for confirmation.

Q: What 's the MOQ and pricing?

A: The page lists a low MOQ and price range (example listing shows approx. US$1.05-1.40/kg); contact supplier for current pricing, MOQ for color runs and bulk discounts.

Product Copy

High-tenacity 900D PP FDY multifilament tape yarn -- factory-dyed, medium coarse, and built for webbing, braided rope and industrial textiles. Tight quality control, fast lead times and large monthly supply. Custom colors available.

Ordering Tips

- Request a physical sample to confirm color, hand and strength before a production order.

- Ask for datasheets showing tenacity, elongation and CV values and any SGS/third-party test reports.

- Provide Pantone or color reference when ordering custom-dyed yarn and confirm MOQ for color runs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!