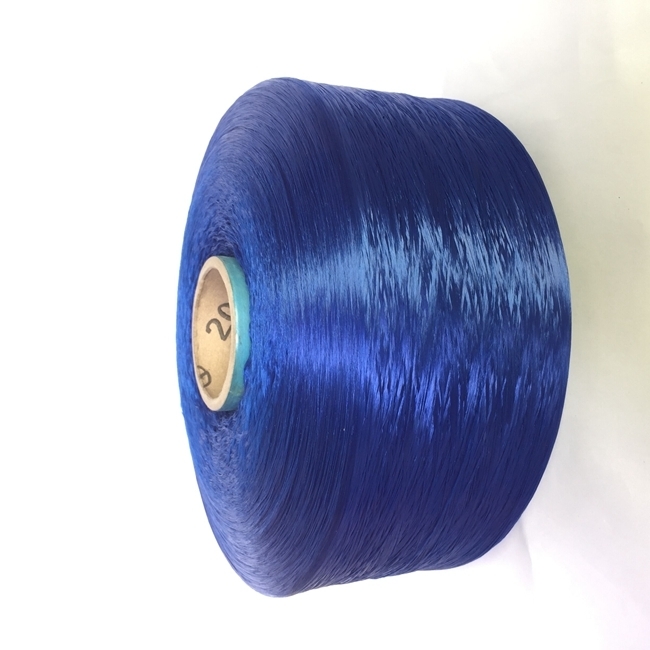

Colored PP Multifilament Yarn — High-Tenacity FDY Polypropylene Yarn for Webbing & Rope

Product Summary

A factory-made colored polypropylene (PP) multifilament yarn engineered for strength and durability in webbing, braided rope, luggage belts and geotextile applications. Offered in FDY (fully drawn yarn) form with a wide range of deniers (300-1680D+), this product supports custom colors and high-volume supply.

Key Parameters & Technical Specifications

- Model: XCF900C10

- Material: 100% polypropylene (PP)

- Technics: FDY (fully drawn yarn), multifilament tape yarn

- Filament counts: 36f / 55f / 60f (common options)

- Available linear densities (Dtex/D): 300D, 450D, 600D, 800D, 840D, 900D, 1000D, 1200D, 1300D, 1680D (and similar ranges)

- Typical tenacity: ≈3.0-3.5 g/d

- Break strength / Tenacity specs: Break strength ≥35.3; tenacity ≥3.5 (depending on grade)

- Elongation at break: ≈20% ±2% (CV of elongation ≤4.0)

- CV linear density / tenacity: Tight quality control--CV of linear density ≤2.0; CV of tenacity ≤6.5

- Oil pick up: 1.0-1.2

- Air-intermingled (if requested): 20-25 pcs/m

- Supply capacity: ~2,500 tons per month

Main Selling Points

- High tenacity & consistent quality: Manufactured to tight CV tolerances for predictable performance in weaving, braiding and webbing.

- Wide denier range: Options from fine to heavy deniers (300D-1680D+) to suit light textiles up to heavy-duty webbing and rope.

- Color customization: Dyed, factory-colored yarn available -- suitable for branding and color-matched production runs. Custom colors supported subject to MOQ.

- Functional features: UV resistance, eco-friendly material (polypropylene), medium coarseness and low oil pickup for downstream processing.

- Competitive supply & lead times: Large monthly capacity and stated ability for relatively fast delivery for bulk orders.

Application Scenarios

- Woven webbing & straps: Seat belts, luggage straps, container belts, cargo webbings.

- Rope & braided lines: Luggage ropes, safety rope, braided or twisted rope for marine/industrial use.

- Geotextiles & industrial fabrics: Filter cloths, wind canvas, anti-fall nets, and other heavy-duty textiles.

- Luggage & accessories: Handles, cords, synthetic bindings where color and tenacity matter.

Packaging & Logistics

- Typical packing: 4 bobbins per sack/box; individual bobbins ~5-7 kg.

- Container loading: ~10 tons per 20' GP; ~23.5 tons per 40' HQ.

- Lead time: Typical delivery within 7-15 days after down payment or an irrevocable L/C (subject to order size and production schedule).

Quality Assurance & Factory Info

Produced by a Guangdong, China-based manufacturer specializing in PP multifilament yarn and webbing; exporter to many global markets. The supplier cites SGS-level quality checks, OEM/ODM capability and in-stock capacity for frequent orders. Production capacity listed at ~2,500 t/month.

Future Trends & Why This Product Remains Relevant

- Shift to durable, low-maintenance synthetics: Polypropylene is increasingly favored for outdoor and industrial textiles because of its resistance to moisture and chemicals and its low weight.

- Demand for colored/brandable materials: As finished goods focus more on visual differentiation, factory-dyed PP yarns reduce downstream dyeing costs and waste.

- Sustainability pressure: Expect more recycled-PP and eco-labeled variants; manufacturers who can offer recycled or low-impact dyeing will have a competitive edge.

These are market-oriented observations; for supplier-specific eco-claims verify certifications with the manufacturer.

Suggested On-Site Product Copy

Premium colored polypropylene multifilament FDY yarn engineered for webbing, braided rope and heavy-duty textiles. Available in 300-1680D, multiple filament counts and custom Pantone-matched colors. High tenacity, UV-resistant and supplied at scale -- ideal for industrial and outdoor applications.

FAQ

Q: Can I get a sample?

A: Yes -- free samples are offered; the customer typically pays express/shipping fees.

Q: How long for samples?

A: In-stock items are generally available within about 3 days.

Q: Can you produce custom colors?

A: Yes. Colors can be customized subject to the supplier's MOQ for custom-dyed runs.

Q: How is quality guaranteed?

A: The factory states strict in-process testing, sampling inspection before shipment and intact packaging to ensure product quality. Ask the supplier for SGS/3rd-party test reports if required.

Q: What's the minimum order quantity (MOQ) and price guide?

A: The listing indicates competitive pricing with typical MOQs and per-kg pricing; contact the supplier for current price breaks, sample policy and MOQ for custom colors.

Call to Action / Ordering Tips

- Request a free sample to confirm color and mechanical properties before placing production orders.

- Ask for a datasheet (tenacity, elongation, CV values) and an SGS or third-party inspection report for large purchases.

- For color matching, provide Pantone codes and confirm MOQ and lead time for custom-dyed runs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!